On our most exclusive products, we go through the process of hand stitching the borders of the mattress. This is an incredibly time consuming exercise, and must be done with a huge amount of skill and precision. Hand-stitching the borders is a way of firming up the boundary walls of the bed, so that when the mattress has pressure applied to it, the sides of the unit will go down in a “concertina” effect rather than bowing out or bulging. On average, it takes one of our skilled craftspeople about 15 hours to hand-stitch a king size mattress, but it gives such a wonderful finish to the product that we think that it’s worth it!

How we make our beds

The Feather and Springs team are as vitally important to our success as our customers and products are. We’re extremely proud to have recruited and trained fantastic people that now all work as part of a family and would like to let you in to how we make our beds...

Mattress Manufacturer of Luxury Beds Hand Crafted In Morecambe

Luxury Hand crafted beds

As an expert handmade mattress company, you can be assured of an exemplary product from Feather & Springs time after time and we would like to introduce you to our process of how we make our beds.

We combine years of experience using master craftsmen with attention to detail to use only the very best of materials.

As mattress manufacturers and hotel bed suppliers with quality at the forefront of everything we do, all of our mattresses goes through an end-to-end journey with quality control checks at every stage.

There are no automated processes involved in the making of a Feather & Springs handmade mattress or how we make our beds from our range – everything is done by hand, checked, then moved onto the next person

Luxury Hand crafted beds

As an expert handmade mattress company, you can be assured of an exemplary product from Feather & Springs time after time.

We combine years of experience using master craftsmen with attention to detail to use only the very best of materials.

As mattress manufacturers and hotel bed suppliers with quality at the forefront of everything we do, all of our mattresses goes through an end-to-end journey with quality control checks at every stage.

There are no automated processes involved in the making of a Feather & Springs handmade mattress from our range – everything is done by hand, checked, then moved onto the next person

mattress manufacturer

The materials for our mattresses are all ethically sourced and we only use the best quality available in our mattresses factory to ensure years of exacting service to our customers.

As well as individual quality control checks, when a mattress has been completed it is then subject to a final overall quality control check.

Only when that has been through these final checks is it signed off and passed as a Feather & Springs mattress ready for delivery.

mattress manufacturer

The materials for our mattresses are all ethically sourced and we only use the best quality available in our mattresses factory to ensure years of exacting service to our customers.

As well as individual quality control checks, when a mattress has been completed it is then subject to a final overall quality control check.

Only when that has been through these final checks is it signed off and passed as a Feather & Springs mattress ready for delivery.

How We Make Our Beds

Each and every mattress we manufacture is handmade in our mattresses factory in Morecambe by our team of incredibly skilled professional craftsmen and women. From the selection of fabrics, fillings, spring systems, foams and linings, all our components are carefully selected by our experts to ensure you have the most appropriate mattress for your needs.

But how do we make our mattresses?

Please scroll or swipe across to read all nine steps and processes in how we make our beds.

The first step, and one of the most important, is to produce the core of the mattress. This will define a lot of the characteristics of your bed, and will allow the other components to do their job effectively.

At Feather and Springs, we know that the springs are incredibly important to the quality of your night’s sleep, and as such we do not offer anything less than a pocket sprung mattress. This is because open coil springs don’t react to weight individually because they are bound together and as such it means that mattresses can become uneven.

Naturally, this isn’t what we expect of our products. As a result, we only use pocket springs. These are different because each spring is located separately within its own pocket, meaning if one spring goes down, none of the other springs surrounding it go down. Each spring acts alone, meaning a much better night’s sleep and a better quality mattress.

Once the core of your mattress has been manufactured to size, the next stage is to apply the frame work. The frame is an integral part of the process because it is what ensures the strength and rigidity of the mattresses, and a poor quality frame can bend and warp over time.

We use a super-strong flat frame that doesn’t flex or bend, and is shaped specifically to each mattress ensuring a perfect fit and the best support possible. We design our mattresses to stand the test of time and this is an important element in our mattress design.

This crucial layer goes directly on top of the framed base, and does a couple of jobs to help the mattress. Firstly, it insulates the springs from the quilted layers to come. This is important as without the layer between the springs and the comfort layer, then each individual spring would be felt through the top and reduce the comfort offered by the bed. Also, this layer is there to offer support and firm up the mattress.

The next stage is to start adding the padding to the mattress. Depending on how soft or firm you would like the mattress to be will dictate what type of quilted material we apply at this stage, as we have a large number of options available.

The quilted fabric is in place purely to soften the mattress and make the bed more comfortable. A softer type of material is used on the top layer to allow the mattress to soften around the contours of your body. We are able to offer either synthetic fillings or natural fillings,

to customer specification.

If you would like to choose to have either Memory Foam or Latex as part of your mattress finish then we add this into the mattress

in place of the quilted layer.

The foam or latex is bonded to the spring system so that it won’t move or slip around; with latex we use two layers of crafted latex foam and bond them together onto the mattress frame. With Memory Foam we use 2 inches of foam to get the optimum effect from its use – more than that and your bed would be too ‘squashy’

.

The ticking is a vital part of your mattress, not least because it is the part you see! It is also the part of the mattress you make physical contact with, and as such it is important the appropriate materials are used to make sure you benefit from all the previous components

we have mentioned.

We have many fabrics we use on our mattresses, all are on display in our showroom, and vary from Coolmax, Tencel and Cashmere, to Damask and velvet top layers. Each one is specially selected to get the optimum finish out of each product, and give your mattress a superior finish. Please talk to us about which finish you think you would prefer. Because we make everything in house, we can finish your mattress in almost anything – even different colours!

Like the coverings, the border on the side of your mattress is an aesthetic component as well as an ergonomic one. As such, we take great time to carefully select the correct fabric that will not only support the walls of the mattress, but also look elegant at the same time.

Tape edging is the part where the borders and the covering layers are sewn together to encapsulate the fillings and bring the bed together as one piece. This is a difficult skill as it is important to have the stitching strong and taught, but exceptionally straight and accurate. Our craftsmen in the workshop go to great lengths to ensure this is done to the best of their ability, and won’t rest until the job is done correctly.

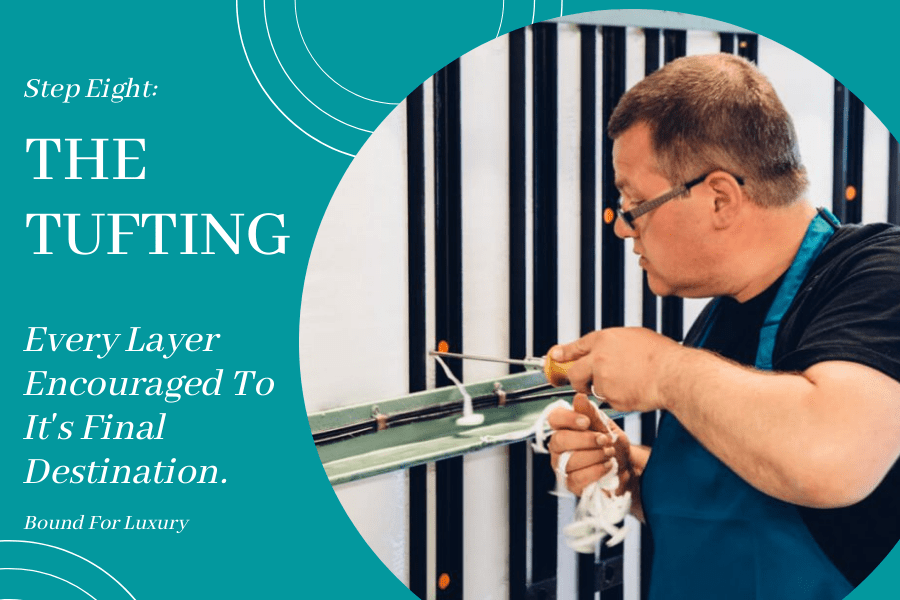

Tufting a mattress is the process of carefully inserting several fabric braces, or “tufts” through the core of the mattress, serving the purpose of holding the numerous layers together and keeping the whole piece compact. This can be an excellent way of improving the lifespan of your mattress and gives the top layer that famous “dimpled” effect we have all come to know.